J DEVSUN MACHINES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to J DEVSUN MACHINES P.LTD.

Roto Gravure Printing Press

DESCRIPTION

Roto Gravure Printing Press is thoroughly classified the factors that contribute to non-productive operations and implemented new devices that minimize non-printing time at almost all major areas in pursuit of optimal reduction of downtime and a higher printability factor.

FEATURES

Unwinder & Rewmder/Infeed & Out feed Unit :

Motorized Precise tension control.

Printing Cylinder Shaft :

Single Bolt clamping with gearbox coupling. 12 " 0 " clock Position

Impression roller :

Tool Less Change over

Doctor Blade Unit :

Multi positioning with innovative features

Gear Box:

Motorized inbuilt mechanism for cross registration.

Ink Tray:

Close to zero Ink Splashing with consideration of less solvent evopration.

Duplex Center Turret Slitter Rewinder Machine

- Shaft less Unwinder with Auto Tension Controller.

- Vacuum Splicing Table.

- Positively Pull Nip Roller through Motorized Drive.

- Programable Auto Positioning for Blade Holder.

- Automatic Centrifugal Air Control for Ball Shaft.

- Pneumatically Fying Knife for Web Splicing.

- Programable Pressure for Layon.

- Auto Reel Removing Provision.

- Auto Core Pick - N - Place Mechanism.

- Fully Automatic Turret Rewinders Operation.

- Users Friendly Operating and Controlling Features.

Doctoring Machine

DESCRIPTION

Doctoring Machine as specially Design for web Inspection and Rewinding applications on Printed Materials. User friendly operating features for real Quality Control Procedure.

FEATURES

Programable Operating Control

Auto Tension Control

Line or Edge Guide Module

Vacuum Splicing Table

Multy Functional facilities as Roll to Roll or Roll to Sheet applications.

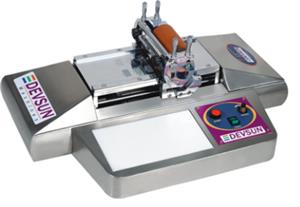

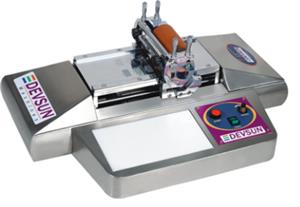

Ink Proofing Device

DESCRIPTION

Ink Proofing Device is develop as most quality improvement features which can be used for color matching, preparation and precise sample of Gravure or Flexo inks and Coating materials.

An applicable device which can be print on film, foil and paper with most precise quality control parameters.

FEATURES

Setting through Micrometer

Suitable for Different setting Parameter

Complete Proofing Function with single attempt

Inbuilt Inspection box

Pneumetically operated

Easy to clean

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.